It's Not About The Patty

I’d like for you to think about the last burger you cooked at home. Think about the buns, the pickles, bacon, guac, fried egg, pepper jelly, fancy mustard, or whatever other special top secret ingredient you like to throw on your creations. Now, think about the patty. First, think about the shape of it. Think about the thickness, the color, the moisture content, the texture, the smell of it. Can you see separate speckles of lean meat and fat or is it all one mushy blob? Did it start off the size of a dinner plate and shrivel up to the shape of a tennis ball once you put some heat to it? Did it break apart while flipping? Did it catch on fire because there were sugars mixed into the grind. Is it bitter, rubbery, tasteless, or spongy? I’m sure at some point in your life you've experienced one or all of these culinary failures either at your own expense or through the embarrassment of a friend that chose the wrong brand. Idiot. Anyways, Bourgeois patties are simple.

First

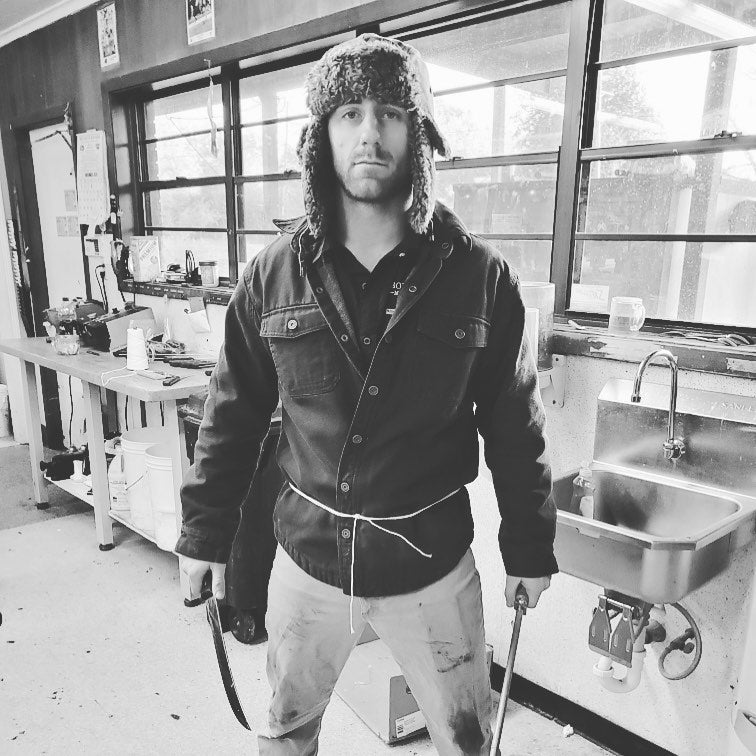

We order whole, bone-in primals of local grass-fed, grass-finished beef. That means we take in two front quarters and two hind quarters, that came off of the same cow sometime within the past 24-48 hours from a slaughterhouse an hour down the road. Once received, our butchers carry these huge quarters of beef over their shoulder with a full bear-hug death-grip from the back cooler all the way up to the front of the shop where they suplex the mass onto the 9 ft long butcher block, making a loud “PLAGGOOP” where the femur bone strikes the wooden table. The kids absolutely love to watch this and it’s something us butchers take a significant amount of pride in. After a quick coffee break, one of our expert butchers takes his 6 inch semi stiff rosewood (Victorinox) and gets to work. If you are ever in the shop and see this happening, stick around. It’s actually entertaining to watch. He will slice, stab, peel, push, pull, and poke his way around the carcass until there is a clean pile of white bones fit for a soup pot. It’s very much a dance of timing and effort. It’s fast; but slow. Chaotic, yet somehow calming. Butchery is an art. It shouldn’t be a means to an end. Although deboning is the first step in our patty making process; to the butcher, it isn’t a task, it is the product.

SECOND

We make our ground meat in huge stainless steel pots that we slide around with long iron s-hooks. We “build” the pots up to 150 lbs of meat with several layers to help balance the grind. Each layer consists of beef (the deboned meat mentioned earlier), fresh pork, and fat. The pork and fat add a depth of flavor, consistency, and moisture to the grind that beef alone can’t attain. During the grinding process we add some soy flour to help the ground meat hold its form while being slapped through the patty machine.

LASTLY

The heaping pot is drug over to the patty machine where it is loaded up onto the hopper. The hopper gravity -feeds the meat between two portion rollers that squeeze and compress a quarter pound of meat into a circular shaped mold plate where it is then slid forward and knocked out by a round cup that fits tightly through the hole in the mold plate with a loud “Pl-A-FFtthwaakopp” immediately followed by the symphony of melodies (played by various gears, belts, springs and zip ties) that are required to cycle the next patty into position. A Bourgeois Butcher knows the timing of this song by heart. It is burned into his memory from the 20,000 times he hears it while making the famous “Fair Burgers” for the Thibodaux Fireman’s Fair year after year.

We take pride in every step of this process. Every time we slide that empty pot to the front butcher table, we are staring at a blank canvas. Next time you buy patties from us I want you to do a few things once you peel off the paper and throw them on the grill:

- Think about the ground meat, not the “patty” or the “burger”.

- Imagine watching the two butchers on the table racing each other with sh*t eating grins as they debone the cow that went into the grinder.

- Now think about the generation of butchers before them doing the same thing 30 years prior.

- Now the generation before them….

STORY TIME:

Long ago, one unlucky little boy once left his hand in the patty machine for a little too long. Surprisingly, it wasn’t the lightning-fast knockout cup that got him; it was actually the slow and steady squeeze of the portion rollers. They roll into one another powered by steel gears with ½ inch teeth that do NOT slip. John Bourgeois is all grown up now and still in the patty business. His shop is down the road over at Bourgeois Smokehouse on Tiger Drive. He has 9 ½ fingers.

By: Shane Thibodaux

I loved reading the ground meat process,,I always wondered how its made, now I know!😁 Thanks for sharing this!

This beautiful prose has awakened a sense of needing a burger in my system. See yall friday for one of them babd boys.

I didn’t know nearly any off the information y’all shared with the public. I must tell that it’s very informative and kept my interest. A good example of how to appreciate the making of, what I at one time thought, a simple burger.👍👏

Leave a comment